When you’ve been around cannabis manufacturing long enough, you learn to separate the hype from the hardware that actually moves the needle. Equipment comes and goes in this space, usually accompanied by flashy language and promises that don’t hold up once the machine is in the room, plugged in, and expected to perform at scale.

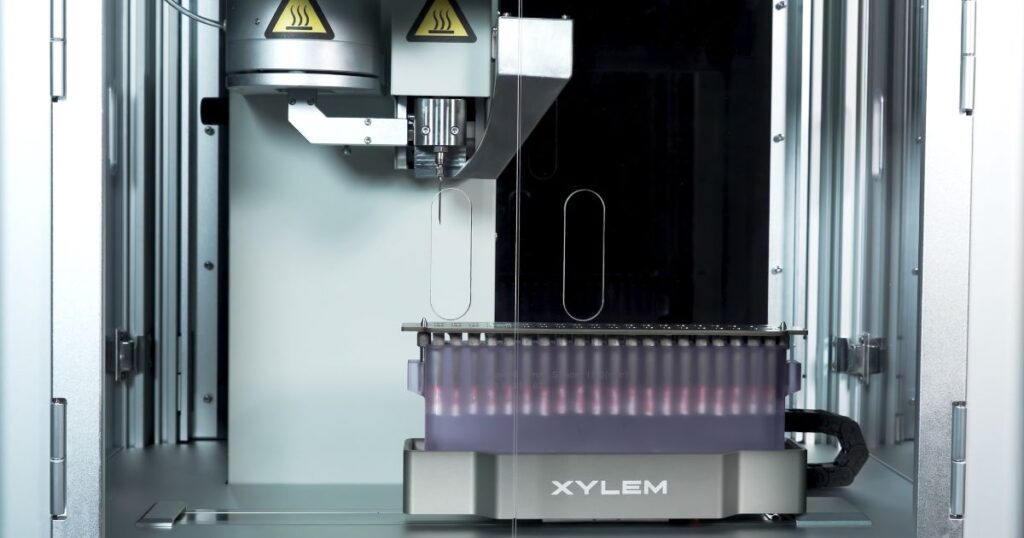

That’s why when a company like Xylem Robotics drops a new model into the market, it deserves a closer look. The Y2 isn’t a total reinvention of the wheel. They didn’t need to reinvent it. What Xylem Robotics has done instead is refine, upgrade, and build upon the success of the Y1 in ways that matter directly to operators, managers, and everyone else who touches the production floor.

The cannabis industry doesn’t need another shiny machine that sits idle after a month of headaches. It needs solutions that acknowledge the brutal reality of manufacturing in regulated markets: compliance demands, razor-thin margins, and a workforce that can’t afford to lose hours to complicated setups or hard-to-service machines.

That’s where the Y2 lands. It’s familiar enough for anyone who has worked with the Y1 to feel right at home, but different enough to make you stop mid-shift and appreciate just how much smoother things are running.

GMP Compliance Without Compromise

If you’ve ever been through a compliance inspection, you know exactly why GMP compliance isn’t a suggestion. It’s survival. Regulators don’t care how well your machine performs if it’s impossible to clean, leaves residue in hard-to-reach corners, or exposes operators to unnecessary risk.

The Y2’s design speaks directly to that pressure. Every single component can be cleaned and wiped down. Nothing is tucked away in an impossible crevice, nothing requires a jury-rigged solution just to pass basic safety checks. It’s fully enclosed, and the system’s sensors aren’t there as window dressing; they’re real safeguards that keep your operators protected and your operation inspection-ready.

That attention to GMP compliance isn’t just about satisfying regulators. It’s about peace of mind for operators who want to focus on output, not whether today’s run will trigger a violation. And it’s about brand reputation in a market where consumers are getting savvier by the day.

No one wants to smoke something that came off a questionable line. When you can tell your retail and wholesale partners that your products were made on equipment that exceeds compliance expectations, you’re not just checking boxes, you’re building trust.

The User Experience Upgrade

Machines don’t run on their own. They need operators, and those operators need to trust that the interface in front of them isn’t going to slow them down. With the Y2, Xylem Robotics doubled down on creating a user experience that feels like a genuine upgrade rather than an afterthought. The redesigned interface isn’t just about aesthetics; it’s about functionality that meets the reality of modern infused pre-roll and hash hole production.

Pre-rolls are the fastest-growing segment in cannabis. Brands are building entire product lines on the back of infused joints, and the margins are simply too good to ignore. But anyone who has spent time in production knows that dialing in consistency on pre-roll infusion settings can be a nightmare.

The Y2 addresses this with added pre-roll setting features built right into the interface. It’s no longer about trying to hack together solutions or layering on manual oversight just to get reliable results. Operators can make adjustments on the fly, dial in the exact specifications they need, and trust that the machine will deliver batch after batch.

This isn’t some tech toy gimmick. It’s real usability baked into the production environment. For manufacturers, that means fewer operator errors, less downtime, and the ability to onboard new staff more quickly. For operators, it’s the difference between fighting with your equipment and actually working with it.

Serviceability Simplified

Every operator has a story about the machine that broke down in the middle of a shift and left the team scrambling for workarounds while waiting for a tech to show up. Time is money in cannabis, and downtime is money lost. One of the most underrated upgrades in the Y2 is its simplified components. This is the kind of detail that doesn’t show up in glossy brochures, but it makes a world of difference when you’re in the trenches.

With the Y2, serviceability doesn’t require a degree in engineering or a three-hour call with tech support. The components are designed to be intuitive, accessible, and easy to maintain. That means less downtime, fewer frustrations, and more predictability in your production schedule. Operators can spend their time running product, not fumbling with tools or waiting on parts.

Tray Stability and Alignment

It might seem like a small detail—tray stability and alignment updates—but anyone who has put serious hours into infused pre-roll manufacturing knows how much havoc poor tray alignment can wreak. Slight shifts in stability can mean inconsistent product, wasted material, and endless recalibration. Xylem Robotics clearly listened to feedback from Y1 users and engineered the Y2 with tray stability that holds up under constant use.

This refinement translates to smoother runs, better consistency, and less stress for operators. Stability doesn’t just save time; it saves material, which directly impacts your bottom line. And alignment updates ensure that every cycle is more predictable, which keeps your output in line with projections.

Simplicity of Design

At the end of the day, simplicity wins. Complex machines might look impressive, but complexity is the enemy of efficiency. The Y2 carries forward the core philosophy of Xylem Robotics design: keep it straightforward, keep it practical, and make it work for the people who use it.

The simplicity of the Y2’s design isn’t about stripping features; it’s about creating an experience where the machine disappears into the workflow. Operators don’t need to overthink every step; they can trust the system to perform, adjust settings easily, clean components quickly, and maintain output without drama.

That kind of simplicity doesn’t come easy. It comes from engineers who actually listen to operators and manufacturers who understand that good design is as much about what you leave out as what you put in.

Continuity Where It Counts

While the Y2 brings meaningful upgrades, it doesn’t reinvent the system just for the sake of novelty. Its core specs and output increased compared to the Y1, and that’s a strength. Manufacturers who already know the Y1 don’t have to worry about retraining their workforce from the ground up. The Y2’s output ability is increased, but with the same proven throughput, and improvements that eliminate pain points without destabilizing what already works.

This continuity also means integration is seamless. You’re not upending your existing workflow. You’re enhancing it. For operators, that continuity is reassurance. They don’t need to question whether the new generation model is going to change the fundamentals of their job. They get the same familiar backbone with the added benefit of meaningful upgrades.

Why It Matters

The cannabis industry is still young, but the demands placed on manufacturers are already brutal. Between compliance, efficiency, labor challenges, and consumer expectations, the margin for error is razor-thin. Machines that overcomplicate the process are a liability. Machines that simplify, safeguard, and stabilize are assets.

The Xylem Robotics Y2 is an asset. It’s not trying to be a flashy reinvention. It’s a refinement, an evolution, a step forward that addresses real-world pain points with practical solutions.

Fully GMP compliant, safer for operators, easier to clean, easier to use, easier to service. The upgrades might sound subtle at first glance, but in the rhythm of daily operations, they add up to something significant.

A Reflection of Where the Industry is Headed

The Xylem Robotics Y2 also tells a bigger story about where cannabis manufacturing is heading. The industry is maturing, and the days of cutting corners or relying on jury-rigged solutions are over. Regulators aren’t easing up. Consumers aren’t lowering their expectations. Manufacturers who want to survive the next decade need equipment that keeps pace with both compliance and consumer demand.

By focusing on GMP compliance, user experience, and design simplicity, Xylem Robotics is signaling that they understand the pressures their customers face. The Y2 isn’t about bells and whistles, it’s about survival, sustainability, and success in an environment that’s only going to get more competitive.