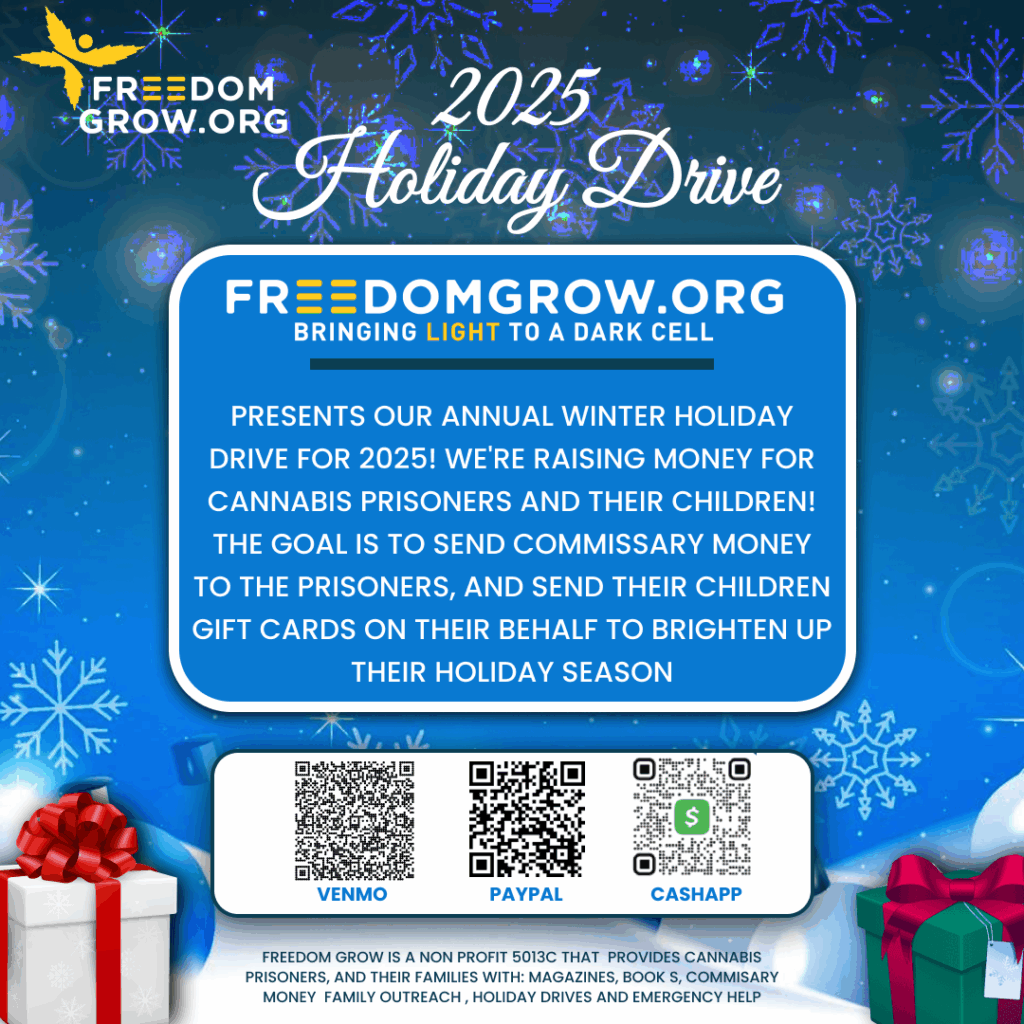

We have heard it said that “Your Pre-roll is your business card” which, when you think about it, gets right to the root of cannabis marketing – is the weed good or not? With the Blackbird from RollPros – the only automated joint machine that literally rolls the weed up instead of simply stuffing a cone – brands and cultivators across the country and beyond can showcase their frostiest crops in a legit Pre-roll product that truly represents their commitment to quality.

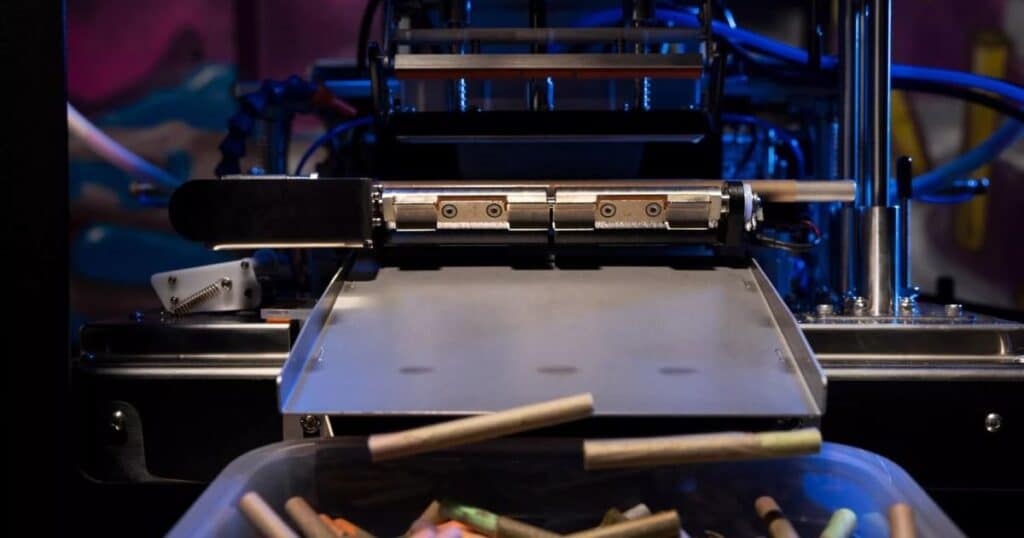

Based in Washington, RollPros founder Kyle Loucks spent many hours during his formative high school and college years deepening his appreciation for the cannabis plant and honing his hobby as a highly talented joint roller.

An engineer by trade, Loucks has a mind wired for bringing concepts to reality. But, have you ever been faced with a challenge or a problem that you just couldn’t solve? Then you step away for a bit, roll one up, spark one up, smoke one up, and return to that challenge with a new perspective and, perhaps, the solution you were looking for all along?

That is the RollPros origin story.

The concept behind RollPros and their flagship product The Blackbird Rolling System seems simple at first glance. Loucks wanted a fully automated machine that would roll a perfect joint with quality, efficiency, and scalability as primary goals. However, it would take years of prototyping and brainstorming… and joint rolling… before The Blackbird would truly take flight.

What makes The Blackbird different from other pre-roll manufacturing options? Just as it is nearly impossible to stuff anything but mids into a pre-rolled cone, it would be just as tough to stuff that answer into a sentence or two, but a recent discussion we had with RollPros was so insightful, we just had to pass along what we learned.

A CLOSER LOOK AT THE BLACKBIRD FROM ROLLPROS

How many joints could you roll in an hour?

What do you think is the most that could possibly be hand-rolled in one hour by the world’s fastest human joint roller?

However high those numbers are, they surely pale in comparison to The Blackbird Rolling System which allows just one operator to produce 750+ always rolled, never stuffed Pre-rolls per hour!

The hopper-style intake utilized by The Blackbird accepts up to 1.5 pounds of freshly harvested and milled sticky, icky, dank weed at a time, and the machine does not need to be shut down if the operator wants to add more of the same strain to continue producing Pre-rolls featuring that particular cultivar.

This ‘fill-on-the-fly’ capability is just the beginning of the brilliance behind The Blackbird.

Picture, if you can, 45,000 empty paper cones just waiting for their fate in a knockbox or similar form of weed-stuffing tech. Imagine how much space all of those mofo’s would take up.

Now picture one continuous roll of unfolded, uncut rolling paper in the substrate of your choice (rice, hemp, etc.) that could produce 45,000 truly rolled Pre-rolls, but only takes up about two square feet of shelf space. That’s called a bobbin and that is what The Blackbird employs to empower just one employee with the ability to produce 6,000+ perfectly rolled Pre-rolls in an average 8-hour shift.

At just 4.00’ x 2.50’ x 3.00’, or roughly the size of a small fridge, The Blackbird unit itself fits through almost any doorway and demands just a very small footprint and access to a standard 110v outlet.

Ok, so it saves you production space, but how about production costs?

With an average consumable material cost of just $0.03/unit, The Blackbird smokes the competition by up to 80% when compared to other market options that run as high as $0.15/unit. Some current Blackbird owners are producing 100,000+ high-quality Pre-rolls per month! That dime-plus per unit starts to add up to some major savings at that scale, but this system saves dollars and makes sense for any operator who mass produces Pre-rolls and cares about the quality of the product in the eyes of the consumer.

As we all know, the real beauty of the cannabis plant is in the diversity of flavors and effects that it offers us, and those nuanced differences between our favorite cultivars are clearly expressed in how the weed grinds, rolls, and smokes.

Some strains benefit from a tighter roll, some come to life if you loosen ‘em up a bit.

For the first time ever, RollPros has created an automated system with an intuitive onboard user interface which allows the operator to dial in specific settings to control exactly how tight or how loose a batch will be rolled, what size diameter the Pre-rolls from that batch will be, and more.The output results from each batch or shift are saved to the cloud and batch or date-specific reports can be easily generated by The Blackbird making it easier than ever for an operation to dial in the optimal settings for every unique strain that they keep in their production rotation.

Operators can integrate a wide variety of tip/crutch styles into the system and even add custom branding options so that the finished products represent them, not some rolling paper company.

This ability for a relatively small machine to automatically kick out custom crafted, masterfully rolled doobies the way that The Blackbird does is what RollPros calls TruRoll technology and because The Blackbird really rolls the weed almost identically to how you’d do it by hand, it allows you to use incredibly fresh cannabis that would never stuff properly into a cone.

[WATCH A BLACKBIRD IN OPERATION WITH THIS ROLLPROS DEMO-ON-DEMAND]

Have you ever tried to stuff a cone with some good weed? How’d that go? The only way to do it at any sort of scale with any real success is to overgrind some overdried weed toss it all in a knockbox and ask gravity to do the rest. That is the SOP for countless failing cannabis brands right now.

On the contrary, RollPros encourages its operators to experiment with flower with a moisture content as high as 10-12% which, in theory, would be some super sticky stuff, but would also (in theory) allow the product more time to reach its final “cured” stage while it makes its way to the retail consumers. Compare that to weed that reached that peak enjoyability level weeks or months before it even got jammed into an imported, pre-crutched cone.

SPARKED BY INNOVATORS LIKE ROLLPROS, PRE-ROLL MARKETS ARE LIT

For many connoisseur-grade cannabis consumers, just the term ‘Pre-roll’ can cause cringey reactions since, for far too long, the quality of the average dispensary Pre-roll typically relegated such products to free First Time Patient gifts or bottom shelf offerings.

The reason for this was simple – trash in, trash out. Pre-rolls were once a way for some brands or shops to try to disguise otherwise unsellable weed and pass it off to unsuspecting custies… and it worked, for a while, at the expense of the reputation of the Pre-roll product category.

However, as cannabis markets emerge and mature, not only here in the U.S. but worldwide, the most popular and best-selling brands in those markets have recognized the growing consumer demand for the convenience and affordability that Pre-rolls provide.

There’s just something primal about sparking up a joint, isn’t there?

The first few hits of a perfectly rolled joint full of fresh fower is the best way to assess and enjoy those buds. This is how the award-winning farmer grades his or her crop and this is how random consumers become loyal customers.

Unfortunately, the labor-intensive act of rolling a perfect joint by hand has historically precluded most brands from even considering this as a manufacturing option. The alternative is what you see on most store shelves – an assortment of Pre-”rolls” in fancy packages that amount to over-dried herb not “rolled” at all, but literally stuffed into mass-produced cones.

There is no comparison between a stuffed cone and a rolled joint full of sticky, trichome-laden, terpene heavy cannabis but the latter has traditionally not been found on dispensary menus as brands just haven’t had the bandwidth to roll super dank weed up for mass production… until now, thanks to Rollpros.

BLACKBIRD-POWERED BRANDS SOAR WITH SUSTAINABLE SCALABILITY

You know that we here at Beard Bros Pharms are staunch advocates for shortening supply chains as much as possible. It’s not just the number of links – or license types – on that chain between the farmer or craftsperson and the consumer, it is the time that gets wasted with weed sitting around aging and waiting to be processed.

One thing that does not get better with age: weed.

One thing that does not sit around at Blackbird-powered facilities: weed.

That fact, along with the ability to roll up tens of thousands of super-fresh Pre-rolls that will be essentially ripening on the way to the consumer, can mitigate the detrimental effects of convoluted supply chains in regulated markets.

RollPros currently has roughly 80 units out in the world producing perfect Pre-rolls right now, including multiple clients who own and operate multiple Blackbird Rolling Systems. This optimization of output didn’t require more real estate, or hiring or training of entire crews. Just another plug and a four-foot footprint.

RollPros manufactures The Blackbird right here in the U.S. and sources the vast majority of its materials and parts domestically and even locally. They provide on-demand shipping for replacement paper bobbins and other supplies, cutting out the need to import flimsy cones from overseas.

The game has changed.

We think that The Blackbird is such a game-changer, it might even have to be a name-changer.

Think about it… a small handful of brands are truly rolling by hand – especially with the HIGH demand for infused Pre-rolls. Aside from them, though, how can anyone who isn’t using The Blackbird refer to their product as a so-called Pre-ROLL if it wasn’t really rolled?

Stop stuffing, start succeeding with real Pre-rolls and RollPros.

Learn more at www.RollPros.com

Enjoyed that first hit? Come chill with us every week at the Friday Sesh for a freshly packed bowl of the week’s best cannabis news!