Driving into Denver by way of St. Louis on the long, flat stretch of I-70, the stories of values-driven brands I encountered in Minnesota and Missouri linger in my mind. These stories share a common thread: high barriers to entry, a maze of legal regulations, and steep costs to establish a brand. One challenge, in particular, stands out—the costly, complex, and often time-consuming process of sourcing packaging.

I pulled into the Grasslands Agency parking lot, where I set up the Scamp Camper for an interview with Alex Cline and Dustin Steerman of Vert Packaging. We sat down in the tiny nook of the camper to discuss the ways in which their unique business model removes massive strain on cannabis brands, both big and small.

Dealing with a Broken System

Steerman and Cline outlined the deep flaws in traditional packaging sourcing. Typically, the process begins by contacting several manufacturers or a broker who sends out requests for proposals to multiplier suppliers, most commonly overseas, to send out requests for proposals (RFPs) to multiple suppliers. Brands must specify their needs in painstaking detail, only to receive inconsistent quotes in return. This portion of the process can be timely and very detail-intensive, requiring a full-time role dedicated to managing the process.

Once a supplier is chosen, creative assets are submitted, kicking off several rounds of proofing, editing, and approvals. The minimum quantities, print capabilities, shipping times, and cannabis industry state-specific packaging compliance specs impact every part of launching a product.

“For example, if a brand is launching just one new product, at minimum, they are likely sourcing a jar and lid, a jar label (or two), a lid-seal sticker, a custom box, and a case pack. At that point, you have five or six layers of packaging to account for,” Steerman explains.

Traditional Packaging Vs. Cannabis-Specific Solutions

In traditional sourcing, one supplier may not have all of those options available, so the brand is forced to piecemeal the packaging from different sources. The process is expansive, timely, detail-intensive, and incredibly expensive. Most packaging sources haven’t supplied cannabis brands, so their knowledge is limited.

Cline, reflecting on his time at Cookies, described the frustrations: “They call me, and I’ll ask, do you have an eighth bag, and they’d say, ‘What’s an eighth? What’s an eighth product’, and it’s like, ok […] you’ve never bought weed before, and that’s fine. There’s nothing wrong with it, but there’s a level of understanding that they do not have, and it makes it harder to do business”.

Cannabis brands operate uniquely, often breaking units by weight, like pounds into eighths or ounces. Traditional suppliers, accustomed to other industries, frequently use arbitrary metrics for their case packs. It’s yet another reason why traditional sourcing may cause unnecessary headaches for cannabis businesses.

Steerman and Cline – both veterans of packaging supply-chain issues and cannabis compliance – knew it was possible to take the work and stress out of the entire process. So they did.

From Frustration to Solution

Steerman got into digital packaging in 2012 and built his first cannabis ancillary between 2017 and 2021. During that time, he got to experience the downfalls of traditional package suppliers and manufacturing firsthand. While things have drastically changed in the last decade-plus, digital has remained the lever for driving growth and disruption for Steerman.

Steerman’s co-founder, Cline, worked for years on the buying side at Lagunitas Brewing Company. He was buying cans by the truckloads each week. Around ten truckloads carrying one hundred thousand 19oz cans each, along with fifteen truckloads of 10oz cans. He later spent four years at Cookies in a similar role, where he met Steerman in the package-sourcing process.

Steerman understood the process of producing the packaging, and Cline understood the headaches of the entire sourcing process from the client side. After lamenting to one another about the downfalls of both sides, they decided they were uniquely qualified to solve those problems together. Vert was born.

Steerman emphasized Vert’s mission, “Vert was founded on this premise, the question ‘How do we elevate, how do we accelerate, craft and small batch cannabis brands?”

But it’s not just small brands they’re poised to support.

“Even medium-sized operators and brands that are growing so fast – how do you give them an agile, nimble supply chain so that they can say yes to an opportunity? Instead of saying, ‘Well, we have to wait for our packaging to arrive.’”

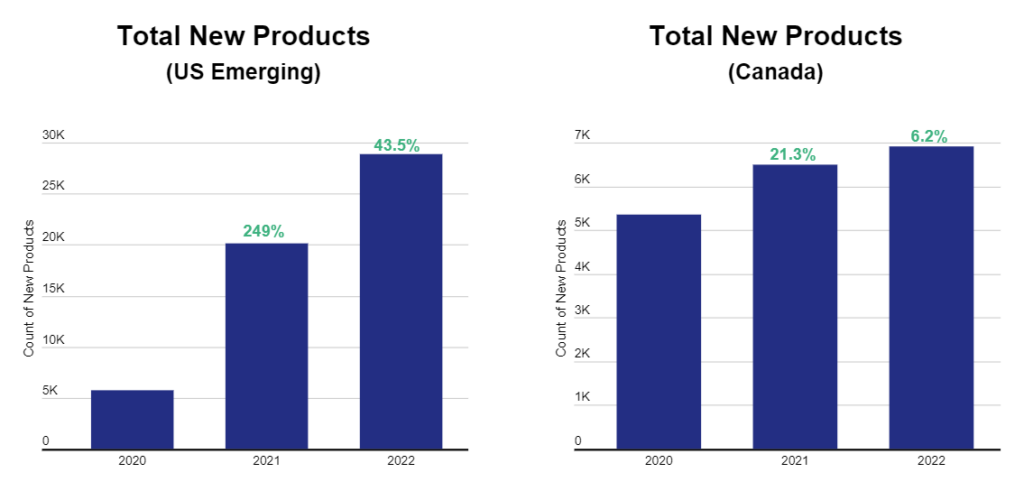

There are legs to that statement. According to Headset data, the US and Canada both saw increases in new products being brought to market YOY from 2020 to 2022.

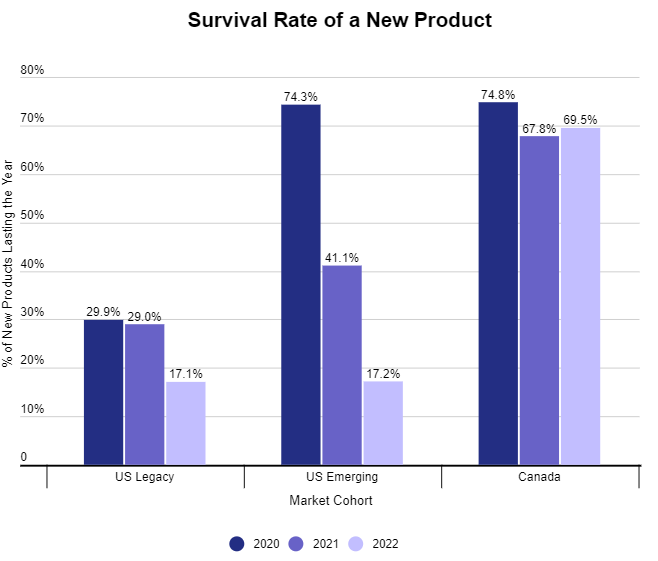

With such quick growth comes the need to impress customers, stay compliant, and manage an elaborate system of package sourcing. When the process of bringing a product to market is so complex, the chances of its survival hang in the balance. Additional data from those years reveals that in the US, the survival rate of new products falls dramatically over the same date range.

In regards to these hurdles, Steerman recognizes the struggle, “We don’t want our customers to ever have to say ‘no,’ or ‘we can’t.’ The answer is, ‘We can do it.’”

A Game-Changing Model

It became apparent to Steerman and Cline that what brands needed most was a partner in their business to reduce the time and money it takes to bring new products to market. Whether they’re servicing a first-time start-up founder or a multi-state brand on an innovation and growth curve, the co-founders have developed tools to help brands stay nimble and agile.

Vert’s approach consolidates a fragmented process. By blending domestic and international supply chains, they offer a one-stop shop for packaging needs, including jars, labels, boxes, and weight-specific case packs. Their in-house capabilities include printing, labeling, and box-making, enabling brands to receive custom packaging within 11 business days. This is a stark contrast to traditional suppliers, who often take months and charge much higher rates.

Vert’s low minimum order quantities (MOQs) and quick turnaround times make their services accessible to both startups and established multi-state operators. Custom packaging options, complete with advanced finishes like foiling and tactile effects, start at $2,500 for 1,000 pieces—a fraction of traditional costs.

Building the Future Of Cannabis Packaging Brick by Brick

In an industry where rising costs and regulatory complexities threaten the livelihood of brands, Vert’s model provides a lifeline. By integrating into their clients’ supply chains, Vert helps brands maintain visibility on inventory and adapt to changing needs without unnecessary spending. In the cannabis marketplace, where brands are often held captive to fast-changing potency and labeling compliance coming down from the state, it’s even more critical for brands to have the option for low minimums and domestic distribution.

Steerman’s vision for Vert is rooted in sustainable growth.

“Nothing replicates work with passion […] It’s all about quality over quantity. Controlled sustainable growth. We know that we will be slowly ramping up over ten years. We aren’t trying to explode overnight. We’re betting on our future clients by structuring ourselves for their success now.”

With the Chinese New Year just around the corner (January 29th, 2025), packaging delays are not just a possibility, they are expected. At a time when cannabis packaging can make or break a brand, having a domestic white-glove concierge service, like Vert, is likely to be a game-changer. As cannabis brands face mounting challenges, Vert’s solutions not only alleviate stress but also set a standard for ethics and strategy in the industry.

At Beard Bros Pharms, we champion solutions that prioritize the unique needs of cannabis brands. By putting ethics and strategy above mere profit, companies like Vert pave the way for a more resilient, waste-conscious, and patient-focused industry. Here’s to a future where every brand, big or small, can turn their vision into reality.