Plant Tissue Culture (PTC) is becoming ubiquitous in the realm of cannabis but is still uncharted territory for many. While it may appear as a recent advancement, the history of PTC dates back well over 100 years.

In 1902, Gottlieb Haberlandt published research in which he described successful attempts to culture individual plant cells in a nutrient-rich medium. Haberlandt’s work was significant, as it demonstrated for the first time that plant tissues could be grown in culture and had the potential to regenerate whole plants.

However, it wasn’t until the early 1960s that the potential for clonal propagation was recognized as new advances in sterilization, media formulation, and plant hormone manipulation allowed for more efficient and reliable plant production in vitro. Even more impactful was the discovery that certain techniques could lead to the eradication of viruses and other pathogens, and maintaining plants in an aseptic environment was a reliable way of preserving the disease-free stock of many important horticulture crops.

Today, PTC is a fundamental part of many agricultural systems and is used to propagate plants with desirable traits, conserve endangered species, and generate plant material for research, breeding, and commercial purposes.

Plant tissue culture is a comprehensive term for all procedures used to grow plant cells, tissues, and organs under aseptic and highly controlled conditions. PTC encompasses everything from clonal propagation to genetic transformations, cryopreservation, bioreactors, pathogen remediation, and much more.

When the primary objective is the production of clones (asexual propagation), this is referred to as micropropagation. This is an important distinction because the central objective of micropropagation is to cleanly produce genetically consistent material with a minimum risk of mutations. Micropropagation has many appeals: controlled year-round production, preservation of elite genetics, and even logistical benefits such as lesser space utilization.

However, its main benefit lies in the ability to culture plants in an environment that is free of biological contaminants such as insects, fungi, bacteria, viruses, and viroids. When plants are properly pathogen indexed and maintained, micropropagation provides exceptional reassurance that the plants generated are free of diseases that significantly reduce yield and other quality parameters. Additionally, it makes obtaining phytosanitary certifications easier for the international movement of material.

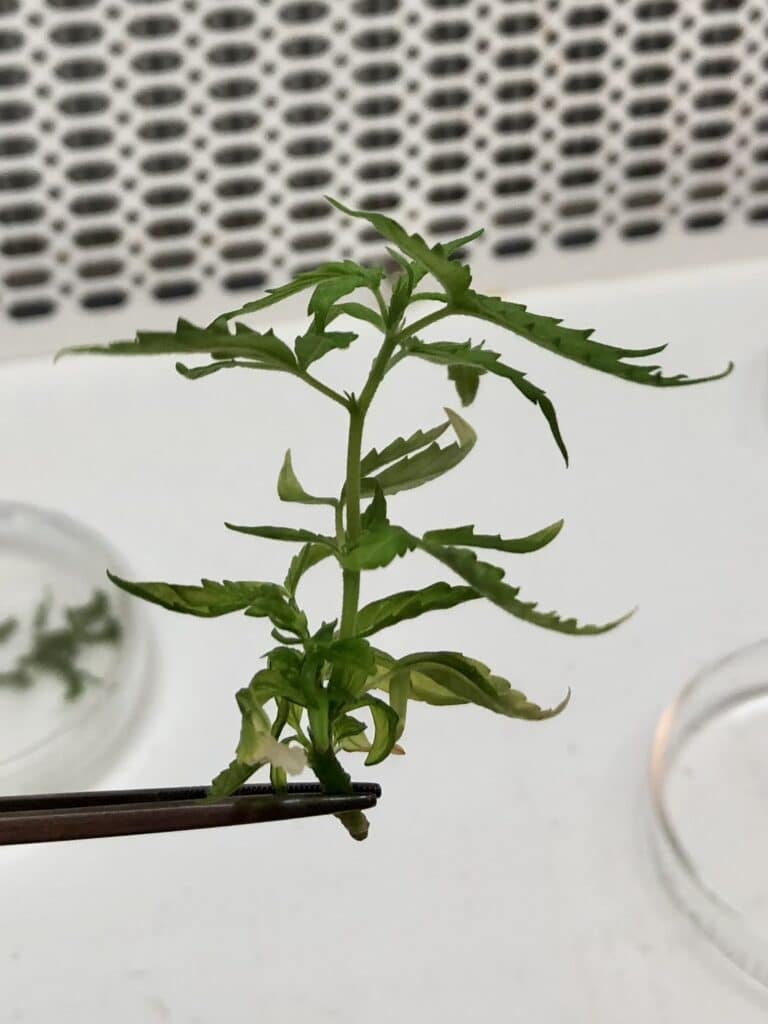

There are several stages in the micropropagation process. The initial step is selecting healthy and disease-free mother stock with desired traits that will be used as the source of explants. The next step is to collect many shoot tips which must then be disinfected to remove any surface contaminants such as bacteria and fungi.

Bleach is the most commonly used surface disinfectant, and this process takes place back in the lab inside a laminar flow hood which removes virtually all particles in the air through HEPA filtration. Following surface disinfection, explants are carefully transferred to test tubes containing sterile nutrient media. As the explants acclimate and grow, they produce new shoots, which are then cut and transferred to fresh media to produce new propagules every several weeks.

This is the multiplication stage and the process is repeated until the desired number of plantlets are produced. Once ready, the plants may be transferred to a rooting medium that contains the necessary hormones, such as auxin, for root growth.

Shoots may also be rooted out of culture and combined with the acclimation stage to maximize production efficiency. Plants must be acclimatized gradually back into the environment to prevent shock and promote growth.

For those outside of a TC lab, the process of propagating plants in culture tubes may seem confusing and daunting. Often, their impression lies in the gelling agent (typically agar), but they may not realize the media is much more complex. The main purpose of agar is to provide a solidified matrix to keep plants upright and is generally considered inert by itself.

There are cases where a gelling agent is not used and a Temporary Immersion System (TIS) is utilized instead, which can be best described as hydroponic tissue culture. Culture media contains macronutrients and micronutrients just as in regular fertilizer, along with vitamins important for development, carbohydrates (sugars), plant growth regulators (cytokinins and auxins, among others), and even other additives such as antioxidants or activated charcoal.

Adding sugar may seem counterintuitive, but plants in culture have been shown to not photosynthesize at full capacity and have different energy requirements than those in the greenhouse or field. While they may be exposed to light, most of the energy is provided by the supplemented sugar.

Each of these inputs can have a significant influence over the quality and speed at which plants in culture grow depending on where they are sourced, the type and concentration used, and even the length of exposure. To complicate things further, different cultivars and even types of explant used can have dramatically different responses and requirements in vitro.

Testing all these factors can be cost and time prohibitive for commercial labs, especially those getting started. Considering this and the amount of conflicting information in circulation is what prompted the Bridgen Micropropagation Lab at Cornell University to conduct further studies on Cannabis micropropagation.

This research, conducted by Conor Stephen, Victor Zayas, Andrei Galic, and Dr. Mark Bridgen, tested various media inputs and practices to understand the best methodology to micro-propagate hemp. The project addressed all stages of micropropagation including considerations on how to best introduce plants into the culture, how to achieve optimal propagation rates, and lastly how to acclimate plants back into the greenhouse. The vigorous cultivar ‘TJs CBD’ was selected as the model organism for the studies. Here are some of the most notable findings:

• Greater initiation success was observed when stock plants were grown from TC in an isolated, pathogen-free environment compared to vegetative cuttings grown in a greenhouse.

• Culture grow-room temperature in the realm of 26-28 °C is optimum for plant growth.

• The media MS, LS, and DKW with vitamins at standard rates are all viable options.

• Optimum sucrose concentration is between 1.5% and 3.0%.

• Media pH of 5.8 or slightly higher is ideal.

• Cytokinins 2iP and BA at rates between 1.0 and 5.0 μM are recommended to improve multiplication rates without adverse effects on plant growth and rooting.

• Acclimation is relatively easy under well-lit, humid conditions.

• Different varieties may have unique environmental and media input requirements for optimal micropropagation.

The data and specific procedures may have less significance to those outside of a commercial tissue culture lab, but growers should still understand how their plants are generated and how the process impacts their own operations. For example, cytokinins are a type of hormone frequently used to accelerate propagation rates as they promote shoot growth, branching, and increase the number of shoots per plant.

However, exposure to high concentrations of cytokinins for long periods of time can lead to unintended effects such as stunting, chlorosis, and even significant delays in rooting. Not to mention that numerous studies have demonstrated prolonged exposure to high concentrations of hormones can lead to genetic mutations.

Growers that source plants from labs that over-use cytokinins may find these plants difficult to root and acclimate. This is not to say that cytokinins are bad, in fact, certain crops require their use of them to grow in vitro. However, over-use leads to toxicity which has been documented in numerous crops, including Cannabis.

Another important consideration is the presence of endophytes which are microbes that persist within a plant’s vascular tissue and can be difficult to eradicate. Many labs use node segments to initiate their plant material which increases the likelihood of endophytic microbes remaining in the plants.

To combat this, labs may overuse antibiotics and microbial suppressants to overcome the contamination and make their operations appear clean on the surface. This is a bad deal for growers as contaminated cultures, whether the contamination is on the surface or endogenous, may lead to significant mortality during the acclimatization process and remain in the mother stock.

Instead, labs should consider initiating small shoot tips or even meristems to limit systemic contamination and not use microbial suppressants in their media so contamination can be observed and removed if present. Frequent pathogen testing should be conducted to ensure no pathogens are being spread.

The notable fear surrounding pathogens such as Hops Latent Viroid (HLVd) and Fusarium illustrates the importance for growers to understand the tissue culture process, how their plants are generated, and what phytosanitary checks have been made.

Unfortunately, with little understanding of the technical nature of PTC, many growers have been taken advantage of. Every lab will claim to have the most optimized media and process, but the truth is the quality and consistency ranges significantly from lab to lab.

That is not to say that labs with different protocols cannot be equally successful. What is important is that plants are healthy with data to prove it, they do not show significant callus growth (which can lead to mutations), and plants root and acclimatize normally.

It is worth mentioning that tissue culture requires specialized equipment, and a high level of expertise, and takes a significant amount of time and resources to get plants into production. This can lead to significant expenses which may discourage growers from adopting the practice.

Regardless of the complexity and potential problems, PTC is extremely valuable and will become more commonplace in the Cannabis industry in the years to come as we continue to strive for higher yields and quality. The ubiquity and understanding of Cannabis TC have accelerated exponentially in the past few years, but we have a long way to go.

About the Authors

Conor Stephen

Conor Stephen is California grown and has a robust knowledge of Cannabis cultivation and tissue culture. Interest in growing the plant led him to pursue a B.S. in Plant Science at Cal Poly, San Luis Obispo where he graduated with the highest distinction. During his time at CP, he worked at Caliva, one of the largest vertically integrated Cannabis companies at the time, and advocated heavily for hemp research at universities throughout the state. He went on to complete his M.S. in Horticulture at Cornell University while conducting research on all stages of hemp micropropagation. Conor was previously U.S. Operations Manager for Segra International where he built and operated two TC labs in partnership with some of the largest grows in California.

You can find Conor here on his LinkedIn

Victor Zayas

Victor Zayas is a seasoned horticulturist with a passion for plant propagation, tissue culture, and breeding. These interests led him to pursue a B.S. degree at the University of Florida, where he majored in Plant Genetics with a focus on Ornamental Horticulture and a minor in Innovation. During his B.S., Victor worked as a research technician for the Floriculture Research Alliance where he gained significant experience in plant propagation and greenhouse management. On top of his own breeding projects, he also managed and evaluated industry-sponsored trials of new varieties of popular ornamentals. Victor transitioned to a tissue culture lab tech position while completing his M.S. in Environmental Horticulture also at UF. Currently, Victor is a Ph.D. candidate at Cornell University where he is working to further develop his skills in plant TC and the breeding of ornamentals and hemp.

Enjoyed that first hit? Come chill with us every week at the Friday Sesh for a freshly packed bowl of the week’s best cannabis news!