Houston-based Xylem Technologies is taking efficiency in manufacturing to a whole new level with innovative automation options offering unrivaled precision and productivity.

Every newly regulated cannabis market in the country is different, but they all seem to suffer from some serious growing pains in their early years.

Every newly regulated cannabis market in the country is different, but they all seem to suffer from some serious growing pains in their early years.

We are seeing it manifest now in California, a state four years into the implementation of a regulated adult-use recreational cannabis market. High costs to enter that market and high taxes once you get in have crippled countless brands to the point where 2022 is a make-or-break year for many.

This is all compounded by steadily falling wholesale prices for some of the most popular products from the flower itself, to the extracts used to fill vape carts, and more.

This tends to lead startups as well as established brands to seek ways to cut costs. Inevitably, and unfortunately, some of those decisions are not made with the best interests of either the consumer or even the employees at the brand itself in mind.

What if there was a way to optimize efficiency and production with precision automation that could immediately raise your profit margins as well as your reputation for producing quality goods?

What if there was a way to optimize efficiency and production with precision automation that could immediately raise your profit margins as well as your reputation for producing quality goods?

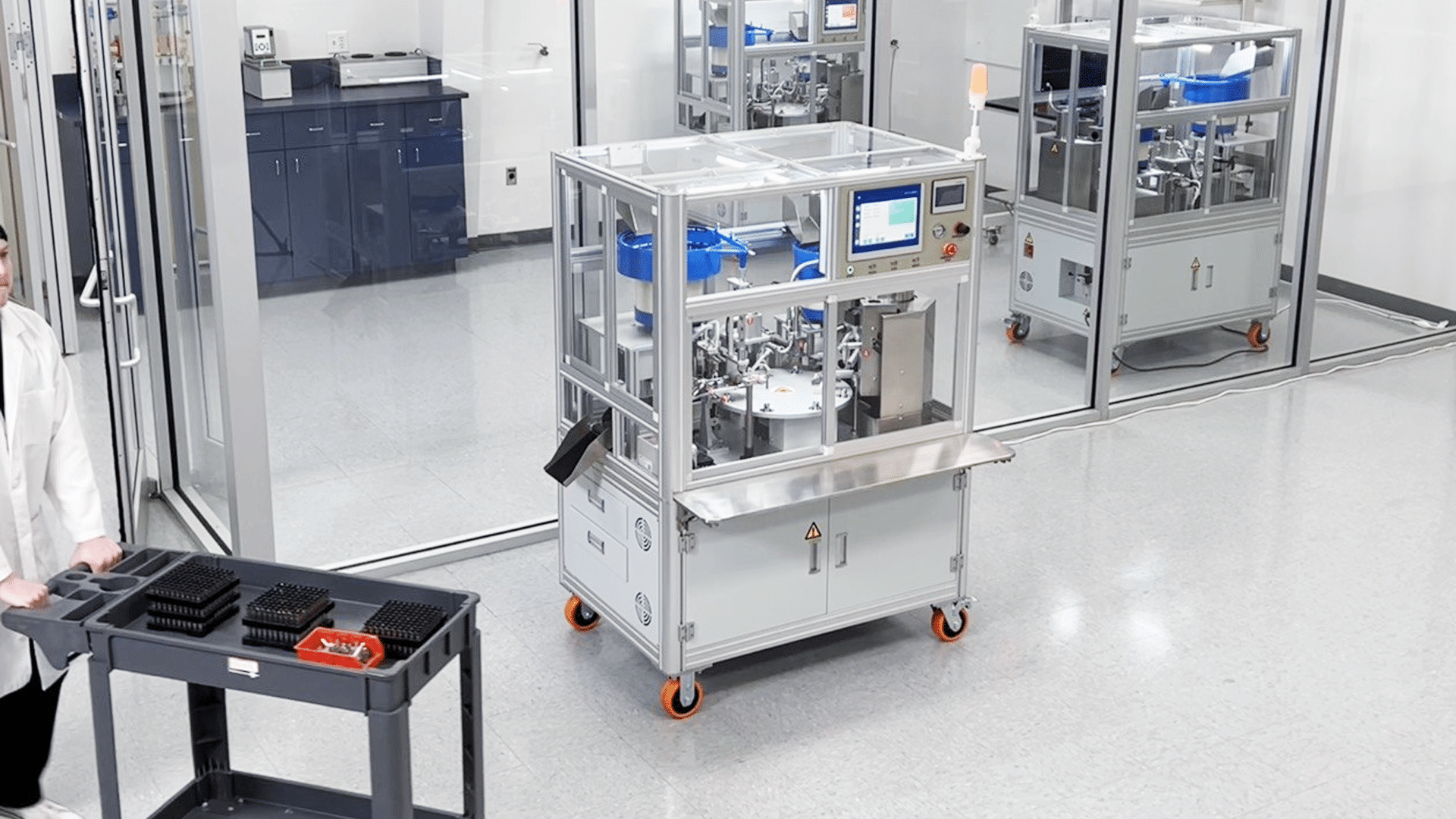

After touching down in Houston, Texas, Bill and Jeff Levers of Beard Bros Pharms got to see firsthand just what that looks like in action with the Xylem-2 Fully Automated Cartridge Filling System from Xylem Technologies.

This one piece of equipment – about the size of a small refrigerator – allows one employee to precisely fill up to 12,000 vape carts in one 8-hour shift, putting an end to the carpal tunnel-inducing tedium that way too many brands are still relying on for vape cart production.

We’re going to dive into the numbers on the Xylem-2 shortly, but you know we like to deal with cool people, not just cool products, here at Beard Bros Pharms. Allow us to break down the background of the mastermind behind Xylem Technologies.

The Roots of Xylem Technologies

Reflecting on his younger days, Jeff Wu the founder of Xylem Technologies now realizes how much of an influence the sea of technical papers and the intriguing scientific equipment that decorated his childhood home had on him.

Wu’s father, an innovator in his own right, was a Ph.D. researcher at Dow Chemical in Freeport, Texas but eventually left to start his own business, and was soon joined by his son in the venture.

Mastering precision pumping equipment at Chemyx Inc., allowed Jeff to understand precision microflow physics as these products are used in Mass Spectrometers to lipid nanoencapsulation for making COVID vaccines. At the same time, Jeff’s father’s calorimetry company, Omnical, spun off a precision temperature control circulator company that became Anova, the best-selling sous vide products in the culinary industry.

The foodies reading this may have heard of the term Sous Vide, translated from French to mean “under vacuum”. This cooking method utilizes water and a pot and some heat. Sounds simple, right?

Go ahead and toss a filet mignon in some boiling water and see how that works out!

Don’t do that, instead the Anova Precision Cooker line heats that swirling water to the precise temperature to cook a thick, juicy steak perfectly to your desired wellness, edge to edge every time.

Did you know that the difference between a rare and a medium-rare steak is just three degrees? Good luck hitting that sweet spot on your backyard BBQ. The Anova has a Bluetooth or even Wifi option so you can monitor your meal’s temperature and readiness from anywhere!

Ok, ok, the Beard Bros don’t write about culinary innovations… but you can find these things in every Target store in the country, so seeing the success of the Anova brand certainly matters and helped to inform us when we took a hard look at Xylem.

During the rise in sales of his game-changing home Sous Vide solution, right around 2014-15, Jeff Wu noticed a strange but recurring trend where one customer might buy a dozen or more of the Anova devices at one time. One customer bought 50 of them in a single order.

With a bit of research, Wu discovered that his device was becoming increasingly popular in the cannabis extraction space where, as we know, precision temperature control is in high demand.

The Anova to this day is still the only product on the market that delivers laboratory-grade precision temperature control for less than $200. This is because Wu and his team created original software for this purpose using a complex “fuzzy logic” controller, rather than a basic PID unit like you see in every e-nail on the market as well as in competing Sous Vide machines on the market.

Wu’s curiosity led him to various cannabis trade shows where he saw other companies claiming to offer a level of precision that he knew only his innovation could truly deliver.

Anova eventually sold and Wu wisely decided to create yet another new company to provide his revolutionary tech to the alluring cannabis space.

There Has to Be a Better Way

In 2018, Jeff Wu was introduced to the team at Eaze, the San Fran-based delivery app founded in 2014. Given a peek behind the curtain, so to speak, Wu saw that the company was selling anywhere from 1.5 to 2 MILLION vape carts per month!

But it was what he saw next that truly shocked him. He saw a room with dozens of employees using syringes and hot plates to fill as many vape cartridges per shift as possible.

With a mind rooted in automation and precision, this primitive process gave Wu an idea of how to optimize this sticky sector of cannabis production and sales.

The precision temperature control software that he had built for Anova was one key element of his new idea. The second was the precision pump technology that he had created in Chemyx for use in precision fluid delivery to fulfill government and pharmaceutical R&D.

Combining these two independently unique pieces of tech, Xylem was born, and by 2020 a better way to fill vaporizer cartridges with high-grade, temperature-sensitive cannabis extracts like live resin was finally available… much to the dismay of pancake griddle manufacturers 😉

The Xylem-2 Benefits the Entire Cannabis Supply Chain

As mentioned, the Xylem-2 Fully Automated Cartridge Filling System allows one employee to kick out anywhere from 1,000 to 1,500 cannabis vape carts per hour.

This employee doesn’t need to be an experienced extraction artist, just attentive and willing to learn a relatively simple user interface – a much more marketable skill for the employee than “Sticky Cart Wiper”.

Compare that to a fair estimate of 3-4 employees manually filling perhaps 3,000-4,000 carts in a single shift… if they’re fast… if they all show up each day… you get the point.

Those extra employees, often one of a company’s largest costs, can now be reassigned to what Wu describes as “value-add roles” like quality control or fit & finish to help establish or expand the brand.

Combining Wu’s deep experience with both precision injection instrumentation and with precise temperature controls, the Xylem-2 might just free up whoever handles your customer service department, too, as complaints about leakage, overfills, underfills, or damaged or unusable vaporizer cartridges due to faulty filling or capping procedures, go up in smoke… or vapor, in this case.

Sometime, somewhere, someone must have gotten a vape cart with dog hair in it, but not if that cart was filled with a Xylem-2!

The Xylem-2 is also virtually self-cleaning, with the extremely limited film of residual cannabis oil being recovered in the process.

The machine delivers real-time and archivable data outlining its efficiency, and the team at Xylem is currently in talks with the top track-and-trace software companies in the industry to eventually integrate their machines directly into a cannabis brand’s state-mandated seed-to-sale software.

Once this is implemented, the Xylem-2 machine will communicate with the cannabis brand’s tracking software so that every time a new vape cart is produced, the company’s inventory is automatically adjusted to subtract an empty cartridge, and their tracking software is auto-updated to subtract the precise amount of oil used to fill that cart.

That’s brilliant and offers brands fewer compliance and tech headaches and more profit.

Designed with the rising popularity of live resin vape carts in mind, the Xylem-2 offers unrivaled temperature controls, allowing for very low-temperature handling of temperature-sensitive cannabis concentrates and extracts.

Not only that, but the amazingly high rate of production of just one Xylem-2 machine alone provides a rapid turn time on high-demand orders of live resin vape carts. Received an order for 30,000 carts on a Monday morning? With just one Xylem-2 device, one trained employee, and a packaging system that can keep up, you could be shipping it out by the end of Wednesday’s shift.

Even if you don’t do that sort of volume, the precision filling and capping capability of the Xylem-2 ensures that your product quality reflects that of your brand.

Learn more about Xylem Technologies and the Xylem-2 Fully Automated Cartridge Filling System at https://xylemtech.com

- Maryland Leads the Way in Cannabis Pardons, Setting an Example for Much-Needed Cannabis Reform

- Military Construction and Veterans Affairs Bill Amendments Could Change Medical Marijuana and MDMA-Assisted Therapy Options for Veterans

- Thailand’s U-Turn on Recreational Cannabis Use

- Chicago Police Department Revises Policy on Searches Based Solely on Marijuana Odor

- Ohio’s Senate Bill 56 Postponed, Leaving Details of Issue 2 Still Unresolved

- Sports Stars and Well Known Entertainers Join Forces Calling on Trump for Cannabis Reform